General Description

The Mill consists of stages with steel fabricated Stress Relived Base. Housing stands are machied to close Tolerance. Shafts are made of EN24 material, flame hardened and ground. Top-Bottom Drive Gears and worm are made of EN24 induction hardened and ground. All the Bearings (22 Nos) are SKF.

The Drive of the Mill from Main Gear Box in between Clutch/Break transmitted to an individual stages by chain coupling. Forced type lubrication provided by all moving parts. Panel Board provided with controls luch Forward-Reverse and Emergency stop in each stage.

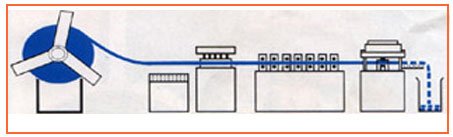

The Complete Forming Line Consists Of.

- Number of Stages Min.Max.(Depends on profile and customers requirements)

- Double End De-Coiler 2-10 Tonnes

- Automatic Cut-off

- Conveyor Table

- Marking Unit

- Roll Toolings

- Counting Unit

| VJ400 TECHNICAL SPECIFICATIONS | |

| Horizontal Centres | 400 mm |

| Vertical Centres | 125 Min. and 225 Max. |

| Rolls Space | 300 |

| Drive Space | 50 mm |

| Main Drive | 15Hp |

| Overall Dimensions | 1 meter wide, 6 meter long |

| Materials to be Used | 0.5 mm to 2.5 mm thick CRCA steel / Aluminium. |

| Other models | VJ250, VJ650, VJ1200 |

Application

1.Building Industry

- Different section of Rolling shutters, Blends, Ceiling and Wall-Panels.Section for Roller

- Doors, Garage and Door Frame and Window Frame.

- Components for Ladder and Scaffolding Cable Ducting.

- Welded Hollow sections for doors and windows.

2.Furniture Manufacturing Industry

- Slider and Casting for Drawers.

- Slide and Rear for Steel Furniture

- Round Square and Rectangular for Steel Furniture.

3.Automobile Industry

- Body work sections, Window channels, Seat Mounting Rails, Silencer Tubes, Two Wheeler

- Rim Mud Guard and Frame Table for Bicycle and Moped Industries.

4.Electrical Industry

- Control Cabinet Frame sections and Panels

- Tubing areas